Military aircraft operate in demanding environments, such as sand, dust clouds, runway debris and even volcanic ash. Micro-particles from these hazards can wreak havoc on gas turbine engines. A team of U.S. Army and academic researchers reviewed a decade worth of studies examining fundamental physics in order to improve aircraft engine performance under extreme conditions. U.S. Army DEVCOM Army Research Laboratory Public Affairs, reports.

Follow Air Recognition on Google News at this link

Researchers from the U.S. Army Combat Capabilities Development Command, known as DEVCOM, Army Research Laboratory, teamed up with colleagues from the University of Maryland, College Park, the University of Cincinnati and the Institute of Thermal Turbomachinery at the Karlsruhe Institute of Technology in Germany, to look at the literature with a critical new eye. Their peer-reviewed work is published in the American Society of Mechanical Engineers, Applied Mechanics Review, “A Critical Review of Physical Models in High-Temperature Multiphase Fluid Dynamics: Turbulent Transport and Particle-Wall Interactions.”

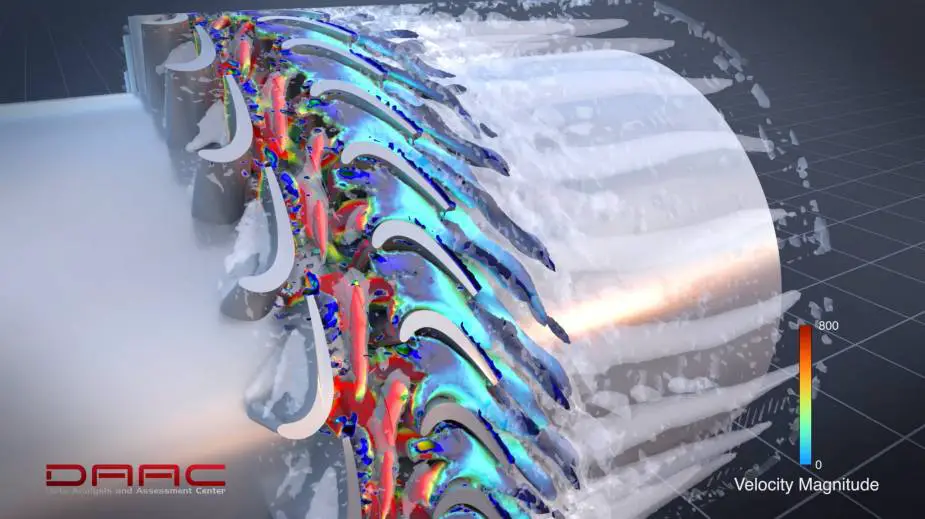

Advanced simulations will provide engineers with enough data to improve future engine performance. (Picture source: U.S. Army)

Advanced simulations will provide engineers with enough data to improve future engine performance. (Picture source: U.S. Army)

“There is a connection between understanding the fundamental physics and the advancement of engine technologies,” said Dr. Luis Bravo, Army researcher. “After reviewing the last decade of state-of-the-art research, we see that the interactions between engine components are often missed in contemporary models and this has a profound impact on predicting unsteady engine performance.”

The review led to a formal partnership, known as a Cooperative Research and Development Agreement, with Pratt and Whitney, the U.S. Navy, University of Maryland and University of Cincinnati. The collaborative effort will use artificial intelligence and machine learning to improve modeling and simulation and develop better design and mitigation solutions.

According to Bravo, the review helped to focus their future research on critical challenges in propulsion and a new research direction leveraging emerging breakthroughs in AI/ML.

NASA and the aviation community published a roadmap for the future and identified one of its grand challenges as the development of computational fluid dynamics full-engine simulation. In a NASA technical report, this vision will revolutionize computational aerosciences by 2030 with advanced simulation capabilities.

Understanding how the components of a gas turbine engine interact under any conditions will be enabled by creating a digital twin. The researchers emphasized that machine learning has increased potential to solve engineering challenges as it matures. They said it will allow them to try out new combustion designs with predictive models and give unique and valuable visualizations.

“I am confident that with the current advancements in artificial intelligence and machine learning tools and high-powered GPU computing resources, we are at the right time now to use this approach to accomplish complex computationally intensive full-scale gas turbine engine simulations in relatively shorter time with high fidelity,” said Dr. Muthuvel Murugan. “AI/ML tools can greatly contribute to performance simulations of high-fidelity digital twin engine models on-the-fly and allow us to use real-time engine operations control and cost-effective sustainment framework of Army aircraft.”

Advanced engine design will be aided by countless high-fidelity simulations from supercomputers in the future.

Ghoshal and his fellow Army researchers have been experimenting with advanced thermal barrier coatings and next-generation materials to protect gas turbine engines from harmful particles. They are also studying advanced aeroengine concepts with academic and industry partners for future Army aircraft. He said their work will not only save lives, but essentially lead to the development of more powerful Army helicopters.